The Peristaltic Pumps Market is witnessing a significant surge in demand worldwide, driven by the increasing need for precise fluid handling in critical applications across various sectors. Peristaltic pumps, also known as hose pumps or tube pumps, operate on the principle of peristalsis, enabling contamination-free pumping of aggressive, viscous, and shear-sensitive fluids. Their non-invasive design, ease of maintenance, and ability to handle corrosive, abrasive, or sensitive media make them indispensable in a variety of industries including pharmaceuticals, food & beverages, water treatment, and chemical processing.

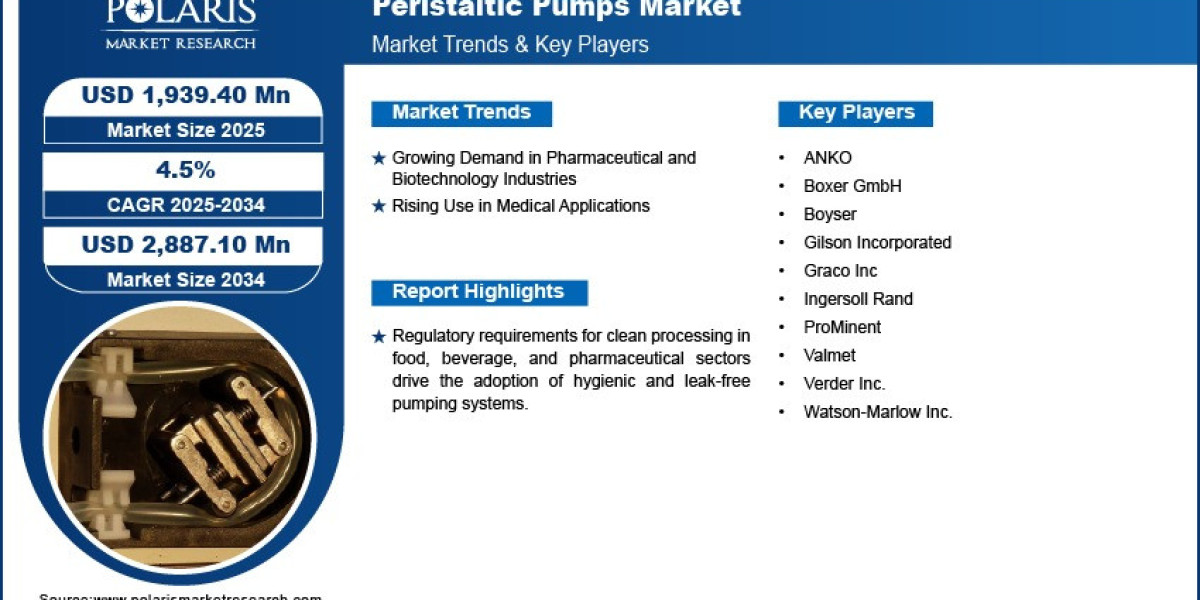

The global peristaltic pumps market size was valued at USD 1,856.42 million in 2024 and is projected to register a CAGR of 4.5% during 2025–2034.

Rising environmental concerns, coupled with the global emphasis on hygienic and contamination-free processes, have further elevated the adoption of peristaltic pump systems. These pumps are increasingly being used in metering, dosing, and chemical injection processes where precision, sterility, and clean-in-place (CIP) functionalities are paramount.

Technological advancements in pump design, such as intelligent control interfaces and digitally integrated monitoring systems, are making peristaltic dosing pumps more efficient, accurate, and reliable. The global trend toward industrial automation, coupled with expanding applications in life sciences and wastewater management, is set to propel the market to new heights in the coming years.

Country-wise Market Trends Analysis

United States

In the United States, the peristaltic pumps market is experiencing strong growth due to increased investments in biotechnology, pharmaceuticals, and clean water infrastructure. The growing demand for fluid handling systems in labs and production facilities for drug manufacturing and sterile fluid transfer is boosting adoption. Furthermore, the country’s stringent environmental and safety regulations have compelled water and wastewater treatment plants to integrate peristaltic dosing pumps for accurate chemical injection and sludge processing. With the rise of automated systems and smart infrastructure, digital control enhancements in hose pumps are gaining traction across industrial sectors.

Canada

Canada's market for peristaltic pumps is expanding steadily, primarily due to rising awareness of clean technology and sustainable water treatment solutions. Municipal water management authorities are increasingly turning to tube pumps for their low-maintenance design and ability to handle harsh chemicals in dosing applications. The pharmaceutical and mining industries are also embracing these pumps for high-purity applications and abrasive slurry handling, respectively. The cold climate conditions across the country also make peristaltic dosing pumps ideal, as they are less prone to freezing-related blockages and offer better reliability in remote installations.

Germany

Germany, being a hub for high-precision engineering and pharmaceuticals, has emerged as a leading European market for peristaltic pumps. The demand is fueled by the country’s strong industrial automation sector, as well as its commitment to environmental sustainability. Water and wastewater management projects increasingly rely on fluid handling systems capable of accurate dosing and chemical compatibility. German manufacturing and R&D institutions are also driving innovations in tube pumps, focusing on energy efficiency, low pulsation flow, and enhanced durability. Cleanroom environments in biotech and diagnostics further benefit from the contamination-free operation of hose pumps.

France

France is experiencing robust demand for peristaltic pumps, particularly in healthcare, food & beverage, and environmental applications. The country’s emphasis on product hygiene and safety has resulted in a preference for contact-free fluid handling systems that reduce cross-contamination risks. In the agricultural sector, peristaltic pumps are used for fertilizer and pesticide metering due to their precision and clog-resistant operation. The country’s investment in green technologies and water conservation initiatives is also fostering the widespread deployment of peristaltic dosing pumps in irrigation systems and municipal water treatment plants.

United Kingdom

The United Kingdom is leveraging peristaltic pump technology as part of its modernization drive in public health, water services, and advanced manufacturing. With an aging water infrastructure and growing urban population, the need for efficient, reliable, and low-maintenance chemical dosing has made tube pumps a popular choice. In life sciences and diagnostics, the emphasis on accuracy and sterile transfer is driving adoption of high-performance hose pumps. Regulatory compliance and digital integration are key trends, with users increasingly seeking pumps equipped with remote monitoring and programmable control interfaces.

Italy

Italy’s market is expanding in alignment with the country's growth in pharmaceutical production, wine and beverage processing, and water management. The ability of peristaltic pumps to handle shear-sensitive and viscous fluids makes them ideal for these applications. Italy's focus on reducing water wastage and chemical overdosing in treatment plants has led to a growing demand for peristaltic dosing pumps with precise flow control. The food-grade nature of many fluid handling systems also aligns well with the country’s strict food safety standards in its agro-food sector.

Spain

Spain’s increasing focus on sustainable agriculture, energy, and public utilities is driving demand for peristaltic pumps. These pumps are widely used for accurate fertilizer and pesticide application, reducing chemical usage while maximizing yield. The water-scarce regions of Spain are also adopting tube pumps in desalination and irrigation systems where precise dosing and resistance to corrosion are essential. In the food processing sector, hose pumps are being employed for clean transfer of viscous fluids, sauces, and dairy products, while maintaining product integrity.

China

China is among the fastest-growing markets for peristaltic pumps, owing to its rapid industrialization, urbanization, and expanding pharmaceutical manufacturing base. The demand for hygienic and contamination-free fluid handling systems is especially strong in life sciences, where peristaltic pumps are used for vaccine production, diagnostics, and intravenous fluid processing. The rise in environmental monitoring and wastewater treatment projects has further elevated the need for peristaltic dosing pumps in chemical injection and sludge dewatering applications. Technological advancements and domestic production of automation-ready hose pumps are making them more accessible across industries.

India

India’s burgeoning healthcare and infrastructure sectors are contributing to the growth of the peristaltic pumps market. The need for accurate, low-cost dosing in municipal and industrial water treatment is spurring demand for peristaltic dosing pumps, particularly in tier-2 and tier-3 cities. Pharmaceutical and diagnostics laboratories are adopting tube pumps for precision liquid handling and sterile transfers. Furthermore, India’s emphasis on local manufacturing under the "Make in India" initiative has catalyzed the domestic production and deployment of fluid handling systems in agriculture, biotech, and mining industries.

Read More @ https://www.polarismarketresearch.com/industry-analysis/peristaltic-pumps-market

Japan

Japan’s highly developed pharmaceutical and semiconductor sectors rely heavily on peristaltic pumps for their clean, precise, and maintenance-friendly operation. The country’s adoption of Industry 4.0 principles has seen the integration of digitally controlled fluid handling systems across manufacturing lines. In biotech and diagnostic applications, tube pumps are valued for their non-shearing properties and contamination prevention. Japan’s focus on aging infrastructure and disaster resilience has also led to the adoption of hose pumps in emergency water treatment units and chemical spill response systems.

South Korea

South Korea is a strong adopter of peristaltic dosing pumps, especially in high-tech industries and medical device manufacturing. The demand for miniaturized and electronically controlled pumps is growing in laboratories, where accuracy and repeatability are essential. As the country shifts towards eco-friendly industrial practices, fluid handling systems are being upgraded to more sustainable, energy-efficient variants. Tube pumps with remote diagnostics and automated calibration are gaining popularity in process plants and chemical facilities.

Australia

Australia’s diverse economy and environmental conditions have created a wide application base for peristaltic pumps. The pumps are used extensively in mining operations for slurry transfer, as well as in agricultural irrigation for chemical dosing. Their rugged construction and ability to handle high solids content make hose pumps a reliable solution in Australia’s remote and harsh environments. In water-scarce areas, peristaltic dosing pumps are used in water recycling and desalination plants to precisely control anti-scaling and disinfecting chemicals.

Brazil

Brazil’s agriculture-dominated economy and growing industrial base are driving demand for peristaltic pumps. In the agrochemical sector, tube pumps are used to apply fertilizers, pesticides, and growth agents with minimal waste. The pharmaceutical industry, which is expanding rapidly in Brazil, also relies on fluid handling systems for sterile drug production. Water treatment in densely populated urban areas is another application where peristaltic dosing pumps are improving operational efficiency and compliance with environmental standards.

United Arab Emirates

The UAE is deploying peristaltic pumps in its large-scale infrastructure and sustainability projects. With limited freshwater resources, desalination plants extensively use hose pumps for brine management and chemical dosing. The healthcare and diagnostics sectors are also driving adoption, especially in hospitals and clinical labs requiring contamination-free and accurate fluid handling systems. Automation and remote monitoring capabilities are becoming increasingly essential for installations in extreme climates and remote desert locations.

Conclusion

The Peristaltic Pumps Market is on a steady growth trajectory, fueled by its versatility, low maintenance, and contamination-free operation. As industries worldwide prioritize hygienic fluid transfer, precise dosing, and sustainable processing, the demand for advanced fluid handling systems is rising across regions. Whether in sterile labs, rugged mines, municipal water plants, or precision agriculture, tube pumps, hose pumps, and peristaltic dosing pumps offer unmatched benefits that align with the future of industrial efficiency and environmental stewardship. With country-wise adoption influenced by sector-specific needs and regulatory standards, the global market is primed for innovation and widespread application across all major economies.

More Trending Latest Reports By Polaris Market Research: